Custom Machine Guarding for Southwire’s Cable Winder

Project Overview:

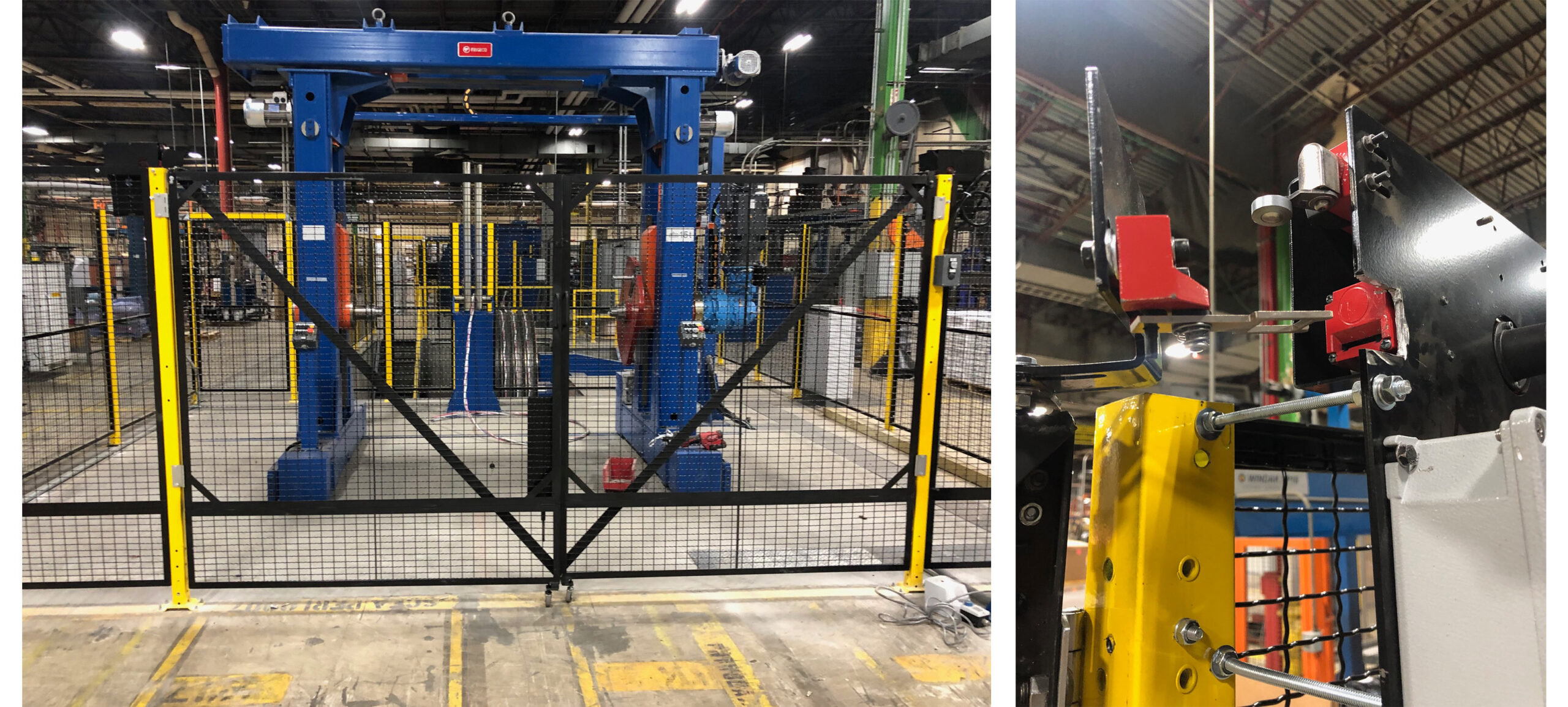

WireCrafters recently partnered with West Georgia Supply to provide a custom machine guarding solution for Southwire, a leading manufacturer of wire and cable products. Southwire sought a reliable and durable guarding solution for its facility to enhance workplace safety and protect equipment operators. Working closely with West Georgia Supply, WireCrafters designed and implemented a tailored machine guarding application that met Southwire’s stringent safety standards and supported their commitment to operational efficiency. This case study highlights the collaboration between WireCrafters and West Georgia Supply, detailing the unique requirements, design considerations, and successful outcomes achieved for Southwire.

Customer Description

Southwire needed a specialized machine guarding solution to enhance the safety of their cable winder spool operation. This application required a design that allowed for the easy movement of large, heavy spools in and out of the guarded area using a forklift. To meet these needs, WireCrafters and West Georgia Supply collaborated to develop a custom double-hinge door, enabling seamless access while maintaining essential safety protocols. The tailored door solution was necessary for Southwire’s workflow, as it provided the flexibility to safely manage wire spools without compromising productivity.

Why Choose WireCrafters?

Southwire partnered with WireCrafters because of their strong relationship with West Georgia Supply. Having collaborated with West Georgia Supply on previous projects, Southwire valued its expertise in industrial safety and its ability to source top-tier products from WireCrafters. The decision was further solidified by WireCrafters’ flexibility in designing custom applications, particularly the double-hinge door that allowed easy forklift access—a critical requirement for Southwire’s cable winder spool operations. This customized approach assured Southwire that WireCrafters could deliver a solution perfectly aligned with their safety and functionality standards.

The WireCrafters Difference

Since 1967, when WireCrafters was established as a wire job shop, It has become the nation’s leading producer of wire partition products. Contrary to traditional systems, our woven and welded wire partitions are based on the simple idea that panels stack one on top of the other between tubular posts to reach the finished partition height. Our ability to create customizable-sized panels sets us apart from all other competitors.

Our mission is to provide our customers with creative solutions for their safety, security, and storage needs while meeting commitments with exceptional quality by people who care.

To learn more about WireCrafters, visit www.wirecrafters.com or follow us on YouTube, LinkedIn, Facebook, and Instagram.