Optimizing Workforce Training with Tailored Safety Systems

Project Overview:

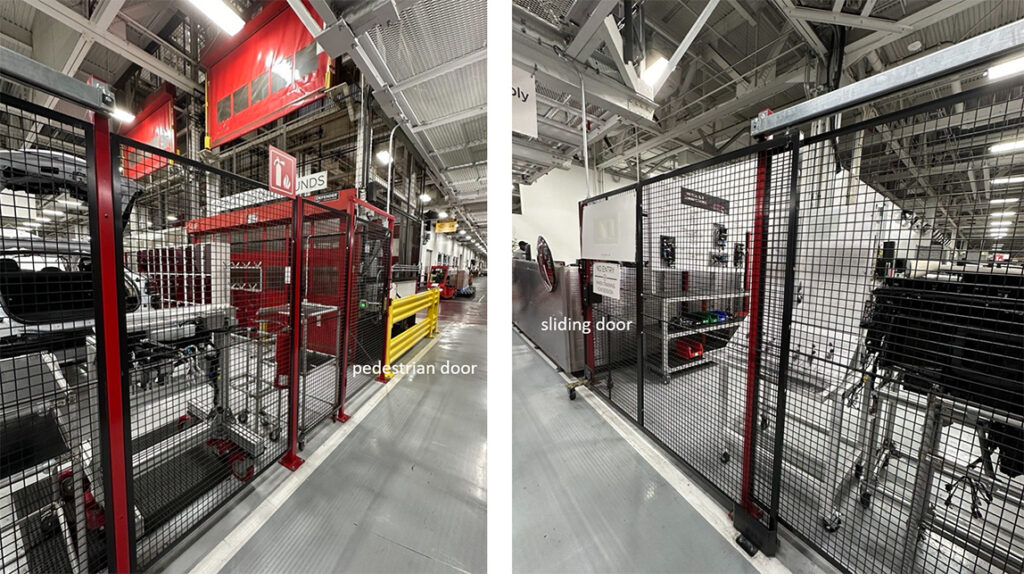

In a recent collaborative effort, WireCrafters joined forces with Bulwark Safety Systems to deliver an innovative machine-guarding solution for a leading car manufacturer. This strategic partnership combined WireCrafters’ industry-leading expertise in creating robust and reliable guarding systems with Bulwark’s cutting-edge safety solutions. Together, they successfully addressed the customer’s challenges, ensuring the highest levels of safety and efficiency for the customer’s operations. The resulting solution enhanced workplace safety and optimized productivity, showcasing the power of collaboration and innovation in industrial safety.

Customer Description

Due to rising sales, the car manufacturer experienced a significant increase in production, necessitating an expansion of its workforce. The manufacturer established training dojos, or cells, to ensure recruits quickly gained the required expertise in car assembly. These automated training cells replicated real-world scenarios, allowing recruits to practice assembling their sections before working on the live production line. These cells required powerful guarding to prevent accidental entry near hazardous areas and to contain stray parts within the training environment to enhance safety.

Why Choose WireCrafters?

Due to several key factors, the customer chose WireCrafters for their machine guarding solution. WireCrafters offered the flexibility to customize the guarding with specific colors, moving beyond the standard black and yellow to match the manufacturer’s request. The quick turnaround time for producing these custom applications was crucial in meeting the tight project deadlines. WireCrafters’ proven quality and deep understanding of the manufacturer’s applications ensured a reliable and effective solution. The ease of installation further cemented WireCrafters as the ideal choice, minimizing downtime and ensuring a smooth implementation process.

The WireCrafters Difference

Since 1967, when WireCrafters was established as a wire job shop, It has become the nation’s leading producer of wire partition products. Contrary to traditional systems, our woven and welded wire partitions are based on the simple idea that panels stack one on top of the other between tubular posts to reach the finished partition height. Our ability to create customizable-sized panels sets us apart from all other competitors.

Our mission is to provide our customers with creative solutions for their safety, security, and storage needs while meeting commitments with exceptional quality by people who care.

To learn more about WireCrafters, visit www.wirecrafters.com or follow us on YouTube, LinkedIn, Facebook, and Instagram.